—— Many Obstacles on the Existing Natural Phytochemical Production Systems ——

Whether it is red wine, coffee or tea, we all know that the quality of products in different years or places of origin will vary greatly. In fact, medicinal plants are also the same. Because the composition and content of phytochemicals in plants, as well as the yield of plants, are very easily affected by the growth environment, such as temperature, rainfall, light, soil nutrients, plant diseases and insect pests.

However, stable plant samples are very important for researchers to analyze and test natural phytochemicals. The industrial scale and stable quality of natural phytochemicals are absolutely critical to the clinical trials and commercialization of selected natural phytochemicals. The instability of plant quality and yield between batches is the main reason for the slow development of phytochemicals.

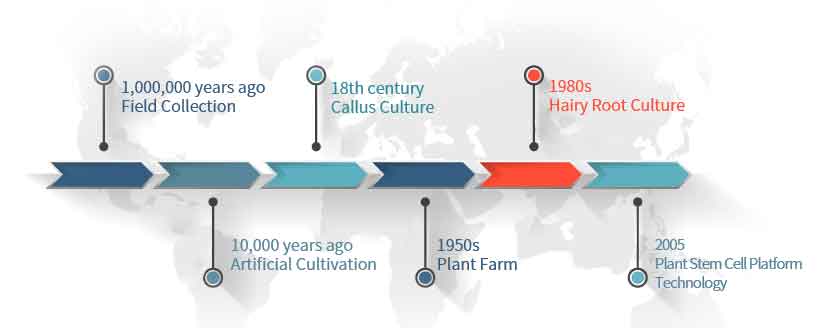

Here are common phytochemicals production systems:

Field Collection

Extracted from wild plants is the typical strategy to obtain many phytochemicals. Sometimes wild species of the source plant present higher pharmaceutical potential than cultivated ones, because they grow in extreme environments for years and may accumulate more rare and high bioactivity phytochemicals. But the wild populations of many rare and high-value plants are being affected and damaged by global warming and human activities.

There are about 1,200 Chinese medicinal materials in common use in China, nearly 70% of them are wild species and account for 60% of total production.

Traditionally, the place of origin is an important reference for evaluating the efficacy of Chinese medicinal materials. Due to environmental and climatic conditions, many medicinal materials can grow in specific areas with high quality and high yield, commonly known as “genuine medicinal materials”.

However, with the increasing market demand for Chinese traditional medicine in recent years, wild herbal resources have been severely damaged.

According to statistics, nearly 3,000 species of plants in China have been endangered, and 60-70% of them are with medicinal value. There are more than 168 medicinal plants listed in “Chinese Rare and Endangered Plants List”, but some species are already extinct.

Therefore, it is difficult to ensure that the method of field collection can always provide sufficient quantity of high-quality plants.

Artificial Cultivation

With growing demand, cultivation has gradually become an important herb supply because of its high and stable biomass yield. At present, there are about 200 kinds of Chinese herbal medicines that can be cultivated in farms. However, due to the limitations of environment, region, technology, growth cycle and other factors, most medicinal materials still fail to achieve artificial cultivation. In addition, changes of planting conditions (such as: planting out of its origins, artificial fertilizers, and shortening of the growth period) will seriously affect the quality and yield of medicinal herbs, making the cultivated herbs lose the composition and efficacy which wild ones have, such as ginseng.

Planting in farms is very sensitive to external climate affecting, so the composition and content of phytochemicals may vary greatly between different batches of medicinal plants. And pesticides, heavy metals, and microorganism are the most common pollution found in Chinese herbal medicine.

Plant Farm

Different from the traditional greenhouse, the plant farm controls the light, temperature, humidity and carbon dioxide concentration in a closed or even dust-free industrialized indoor environment, and uses multi-layer shelves and artificial culture media for planting. This system produces medicinal plants with low bacterial count, no pesticides, no heavy metals, and stable quality.

However, compared to the soil cultivation method, plants produced by the plant farm have a shorter shelf life and are easily perishable. With the high cost of equipment and electricity, plant farms are currently only suitable for high-yield crops with short growing period, multiple harvesting cycles, planting easily, and scale-up easily.

Some of the rare phytochemicals in medicinal plants only be produced under extreme conditions which are difficult to represent in this system. For example, years of growing of ginseng is necessary for ginsenosides accumulation, and nutrients in snow lotus are only produced in extremely cold and lower oxygen environments.

Callus Culture

New plant branches and leaves will be able to grow from the wound soon after branches broken. This is because the mature tissue in the wound will undergo a “dedifferentiation” process and turn into incompletely differentiated and immature callus. The callus cells function like stem cells and can re-differentiate into new plant tissues to repair wounds, or grow into new plants in a particular environment.

The suspension culture of callus cells in the liquid culture medium can not only accelerate the cell growth but also easily increase the biomass yield. This system has been applied to the production of gene transfer plants, and some medicinal plant phytochemicals, such as paclitaxel and vincristine.

However, genetic variation (DNA transposition, recombination) occurs during dedifferentiation and because callus is induced from multiple tissue types, callus are heterogeneous and this feature results in high variability during culture period such as large cell aggregation, etc. And this contributes slow growing and low production of phytochemicals, which may limit the possibility of industrial-scale production of some phytochemicals by callus suspension.

Hairy Root Culture

Plant hairy root culture are generated following infection with the bacteria Agrobacterium rhizogenes of the source plant. They have a high grow rate in the absence of exogenous phytohormones. Hairy root cultures are relatively easy to maintain and are genetically stable.

Hairy root belongs to hormone autotrophic type, which has the characteristics of high content of active ingredients, stable physiology, biochemistry and heredity, and easy to operate and control. It can also synthesize many substances that cannot be synthesized by suspension cell culture. The yield of some products is even higher than that of normal plants cultivation and suspension cell culture.

Hairy roots were differentiated organs which have higher metabolic activities. In some cases, they could produce more phytochemicals, compare to the callus culture system. Hairy root culture systems are already used for production of ginsenosides, atropine, nicotine, etc.

However, only phytochemicals synthesized within the roots of the given source plant would be produced by the hairy root system. And appropriate bioreactor is critical for industrial-scale production.

—— A New Natural Phytochemical Production System ——

The successful isolation of plant stem cells (CMC) provides a new production system for natural phytochemicals. The plant stem cell characteristics of CMCs could break through the limitations of previous phytochemicals production systems, especially the callus culture, and produce natural phytochemicals very efficiently.

Plant stem cells have the following characteristics:

1. Stable Productivity:

Plant stem cells (CMC) have eternal vitality because they contain a lot of telomerase, which protects the telomeres of chromosomes from being destroyed by cell division. Thus, even in long-term subculture, plant stem cells (CMC) do not age and undergo genetic mutations. For example, the stem cells of wild ginseng isolated by PIPSCI in 2005 have been cultured for more than 10 years, and no variation has been found. Therefore, under suitable culture environment, plant stem cells (CMC) can be used as a long-term stable platform to produce and supply natural phytochemicals.

2. High Phytochemical Biosynthesis Activity:

Because plant stem cells (CMC) have more complete gene information and gene expression patterns, they can be cultured in different environments in the laboratory to obtain different combinations of phytochemicals or higher content of specific phytochemicals, and even to discover new effective ingredients beneficial to human beings.

Therefore, it can break through the limitations of all previous methods of phytochemicals production, and is far better than the existing technologies in the fields of biomass growth and the production of secondary metabolites, and can well apply plant stem cells (CMC) to the commercial mass production of target active ingredients. Moreover, using plant stem cell (CMC) technology, we can amplify the rarest and most effective components in nature. Completely break the limitation of time and space, put many research and development achievements which are “stuck in the laboratory” into mass production, so as to provide the most safe, effective and natural components for the market.

Meanwhile, the new plant stem cell (CMC) natural phytochemicals production system created by PIPSCI also has the following four advantages:

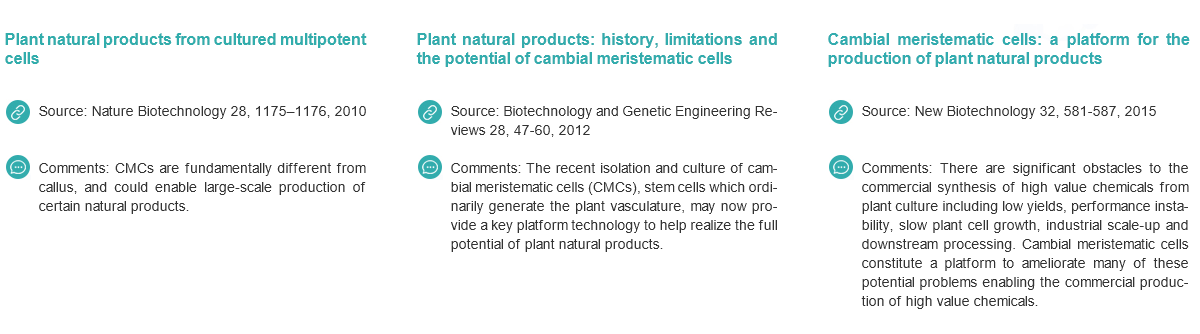

—— The applications of CMCs in the production of natural phytochemicals have get more and more attentions ——